Case Study of Improving VSM and Extending to

Improve EnPI and Complete GHG Emission

Reporting

VSM + EMS + GHG Reporting

VSM + EMS + GHG Reporting

2

Company Level : Factory and Business Management

-> Company and City Level : City Planning and Development

-> Countries Level : Global GHG Information and Emission Trading

Value Stream Mapping

Energy Management System

Green House Gas Emission Reporting

VSM – Lean Production

3

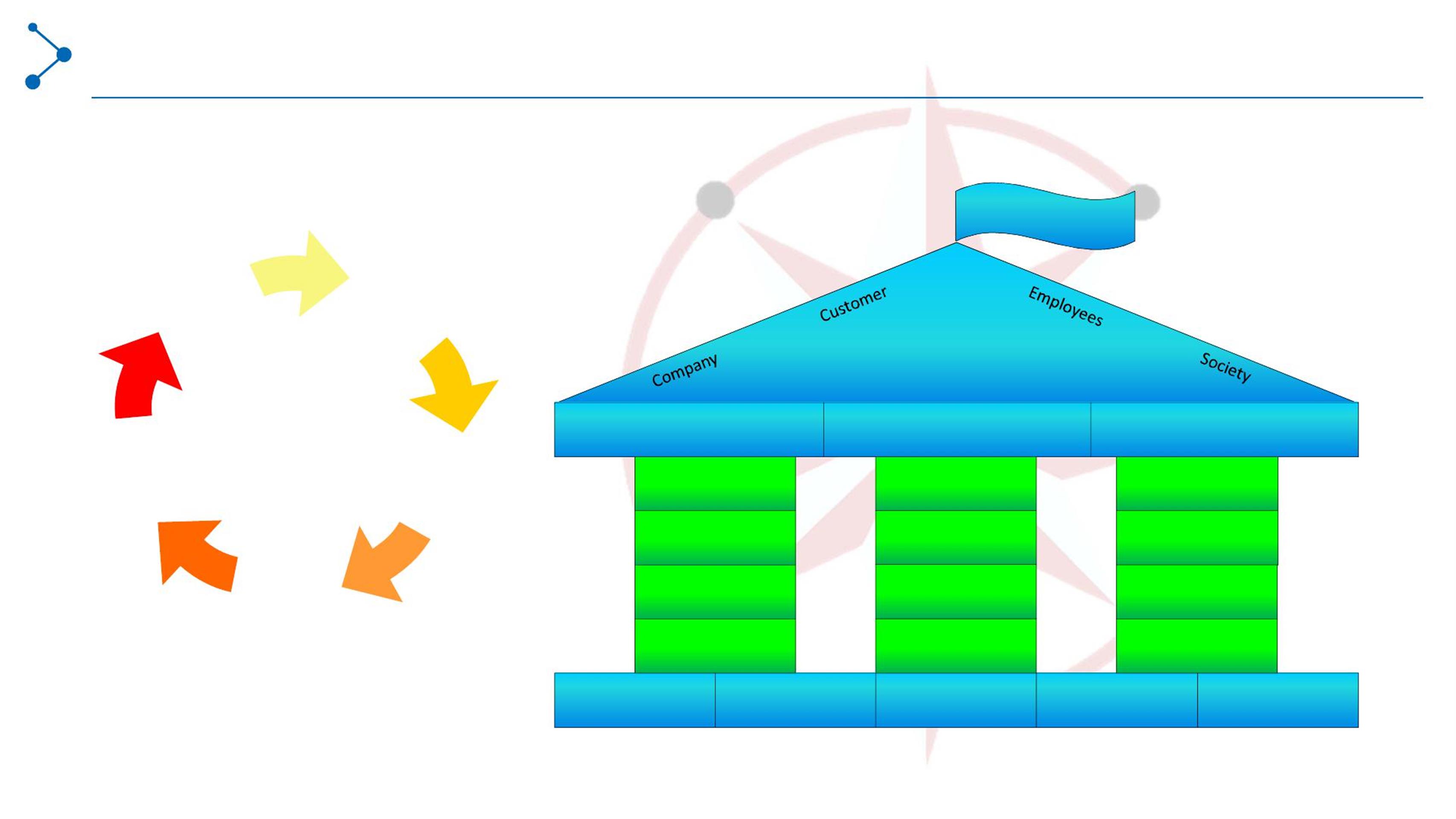

Lean Production : TPS / TOYOTA Production System

平准化生产 5S 目视化看板消除浪费

团队合理化

改善

全面生产维护

价值溪流

拉式生产

快速换线

多能工

标准化

矩阵式管理

同步工程 持续改善

自动化生产

全面质量管理

精益生产系统

防错

全员参与 质量第一及时化

公司赚钱 客户满意

员工获利 回馈社会

Leveling

Production

5S

Visual

Management

WasteEliminationTeamWork

TPM

VSM

PullProduction

SMED

Multi‐SkillWorker

Standardization

Matrix

Organization

Concurrent

Engineering

Continual

Improvement

Automation

TQM

LeanProduction

ErrorProofing

EmployeesInvolvement QualityFirstJIT

CompanyProfitabilityCustomersSatisfaction

EmployeesBenefitSociety Contribution

VA

VSM

FLOW

PULL

PERFECTION

Lean Production

VSM

4

VSM / Value Stream Mapping

VSM

NVA / Non-

Value Added

VA / Value

Added

NNVA /

Necessary

NVA

Value Stream Mapping

Supplier Production Plan Customer

Production Flow

5

ISO 50001

5.Leadership

7.Supp

ort

8.Opera

tion

9.Perfor

mance

Evaluati

on

6.PLann

ing

10.Impr

oveme

nt

P

C

D

A

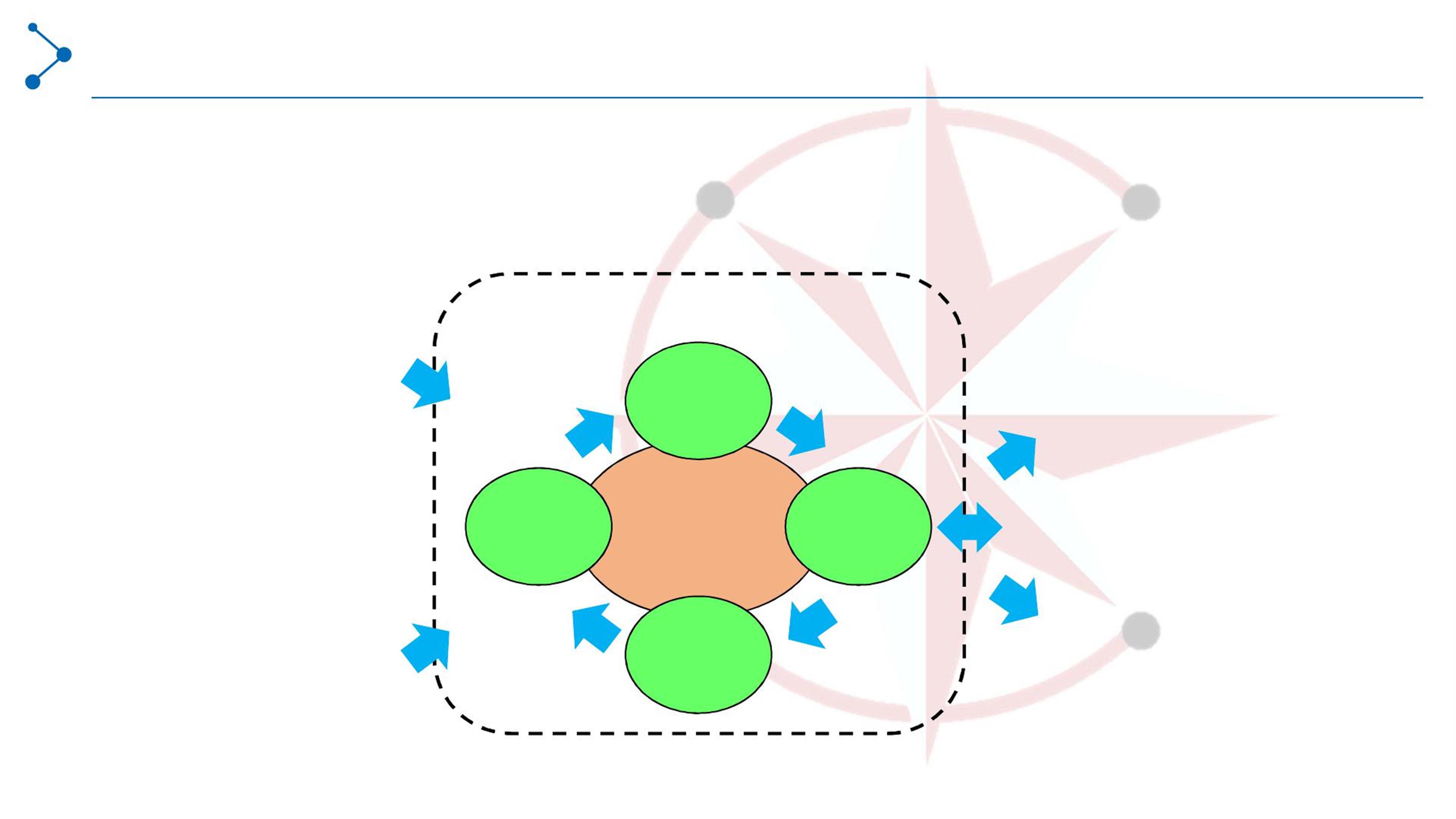

Scope of EMS

Internal and

External issues

4.

Context of

the

Organization

Stakeholder,

needs and

Expectation of

Interested

Parties

Expectation of EMS

Continual Improvement

• Efficiency Improvement

• Energy Consuming Improvement

Other Expectation

• Reduce energy cost

• Target of climate change

• More reliability

• Increase using of recycling energy

Continual Improvement on EnMS

• Improve the suitability, adequacy,

and effectiveness of the system

• Integration with development

strategy

ISO 50001 / EMS / Energy Management System = GB/T 23331:

To identify SEUs / Sustainable Energy Utilities, set up EnPI / Energy Performance Indicator, EnB / Energy Baseline,

targets, and necessary management system, in order to get continuous energy performance improvement.